Cool as Ice

Design and construct a prototype intercooler which will satisfy agreed quality control constraints.

Problem

Intercoolers are used as a cooling mechanism, for instance for a car engine, by maximising the air-flow around the engine.

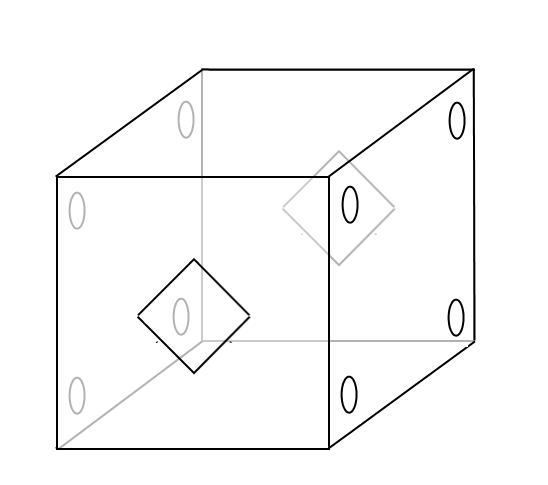

Your task is to design and construct a prototype intercooler, based on a cube, to house a model engine which requires cooling.

Intercooler Specifications

- two opposing faces to be punctured by a diamond shaped hole in the centre, which should be as large as possible without weakening the structure or allowing the 'engine' to fall out

- the other two opposing faces to be punctured by 4 holes to take support tubes (drinking straws will be used in the prototype)

- the intercooler must support the engine when suspended by the support tubes

You have available to you:

- A3 sheet of card

- Scrap paper

- rulers, glue-sticks, pencils, scissors

- 4 drinking straws

- 1 model engine (you could model this with a cube constructed of 4×4×4 multi-link cubes for A3 card)

Key questions you should consider before starting

- What do you need to know/decide to complete this task?

- What tasks will each group member have?

- How will you make sure the coolers pass quality control?

Teachers' Resources

Why do this activity?

The benefit of this activity is the emphasis on quality. Construction skills such as perpendicular bisectors and diagonals could be utilised here to show their increased accuracy over simple measuring.

Students are asked to make an accurate construction of a net from card, and make it up into a finished product. This will require groups to:

- communicate clearly and accurately between themselves, and to display their product to the class, demonstrating that it satisfies quality control constraints

- work from a deliberately 'vague' brief - this will require them to discuss how they are going to plan their prototype, how they are going to construct it, and how they are going to ensure that it passes quality control

Possible approach

This would be an ideal opportunity for the Maths and Design Technology departments to work together on a joint project. If this is not feasible, then perhaps a DT specialist could visit the maths lesson as a consultant.

Initial discussion with the whole class should cover what the brief is actually asking students to do, and crucially what level of quality control will operate - for instance, how much tolerance will there be on the positioning of the diamond holes and the holes for the support tubes.

Once students are clear about the brief, and about the level of accuracy that is necessary, then groups should plan their design. To avoid wasting card, they could make an initial prototype with scrap paper, and check that they understand what they are doing, and that their design will work.

Key questions

- What do you need to know/decide to complete this task?

- What tasks will each group member have?

- How will you make sure the coolers pass quality control?

- How can you ensure that the diamond-shaped holes are centrally positioned?

- How can you ensure that the holes for the supporting straws line up?

Possible extension

What would change if the rods had an angle of elevation of 15 degrees?

Possible support

Make a rough prototype with the whole class from scrap paper, so that everyone is absolutely clear about what they are being asked to design, and what the issues are in ensuring that the finished products meet the agreed quality control constraints.